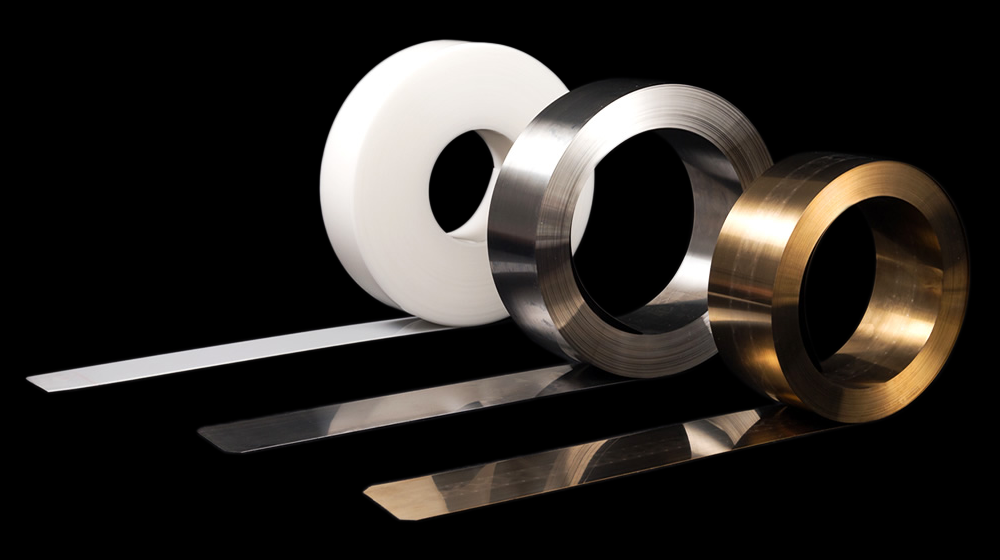

As pure and refined as traditional Katana steels

Using high-quality steel for doctor blades is essential for achieving precision, durability, and consistent performance in demanding printing and coating applications. At Fuji Shoko, we are dedicated to using only steel that meets the highest standards of straightness and flatness to ensure optimal blade performance. Backed by over 40 years of research and development, our proprietary metal processing techniques significantly reduce impurities, producing a cleaner, more stable material. This refined process also promotes the formation of nano-structures within the steel, which enhances uniform blade wear and extends durability over time. As a result, our doctor blades offer superior resistance to wear, abrasion, and corrosion—leading to longer service life, fewer replacements, and reduced maintenance costs.