Introducing the KATANA® Doctor Blade series

designed with unmatched precision and performance

With a passion for craftsmanship, Fuji Shoko is proud to develop fine doctor blade with trusted quality, meticulously designed and manufactured in Japan from start to finish.

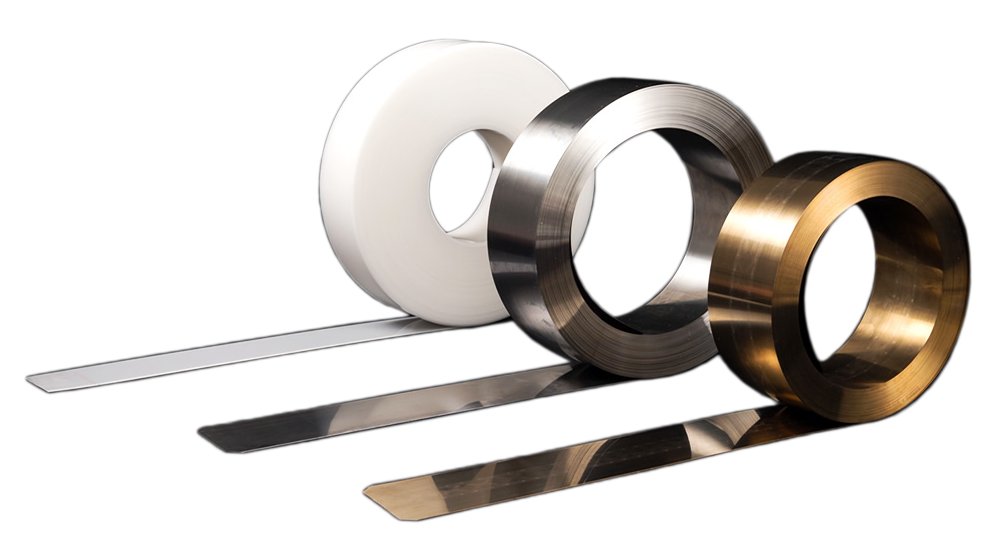

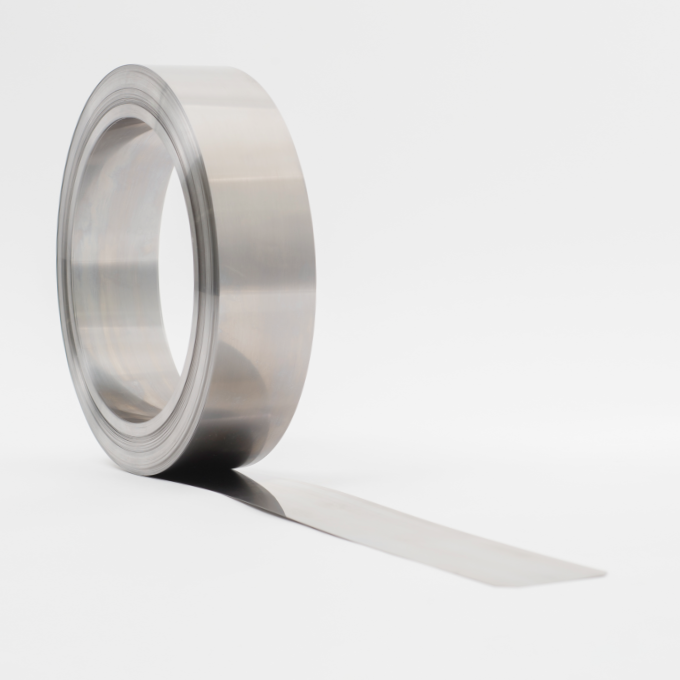

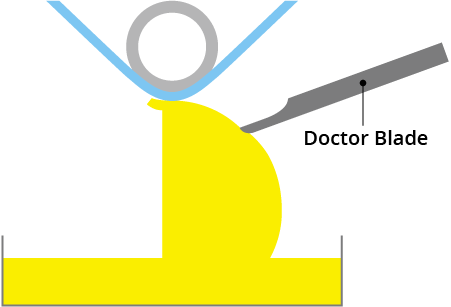

Our Katana® Doctor Blade series come in high quality Ceramic, Steel, and Plastic – all designed to achieve quality web printing and coating in every gravure/flexo application.

Our commitment to using premium materials, equipment, and constant innovation allow us to deliver highly functional, high-performance products tailored to the demands of the printing industry.

Through the visualization and standardization of technical processes, Fuji Shoko not only enhances product quality but also delivers cost efficiency to its customers. This commitment to innovation, reliability, and operational excellence has established Fuji Shoko as a trusted partner in delivering superior-quality solutions across diverse applications.