Introducing the KATANA® Doctor Blade series

designed with unmatched precision and performance

With a passion for craftsmanship, Fuji Shoko is proud to develop fine doctor blade with trusted quality, meticulously designed and manufactured in Japan from start to finish.

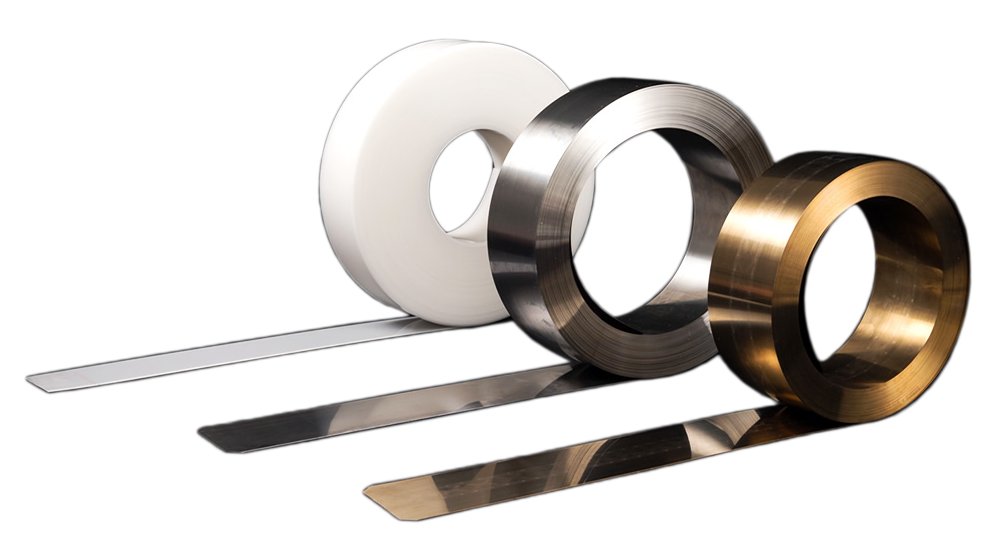

Our Katana® Doctor Blade series come in high quality Ceramic, Steel, and Plastic – all designed to achieve quality web printing and coating in every gravure/flexo application.

Ceramic Doctor Hi-Blade®

Ceramic Doctor Hi-Blade® is our highest quality ceramic-coated model, offering excellent resistance against wear and abrasion.

Our special ceramic coating improves the wiping quality and blade life. Since we introduced the world’s first rolled ceramic-coated doctor blade in the 1980s, we have improved the quality to a satisfactory level that has earned us the trust of our customers as a pioneer in ceramic coatings.

Excellent resistance against wear and abrasion

Our special ceramic coating improves the wiping quality and blade life

Made from high-purity, high carbon steel alloy

Manufactured under stringent quality control, from materials to sharpening and final inspection

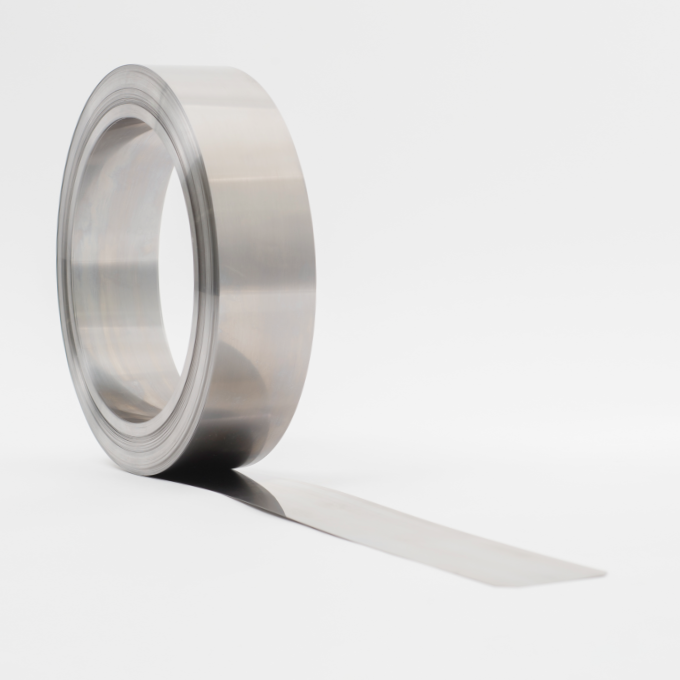

Steel Doctor Hi-Blade®

Steel Doctor Hi-Blade® is manufactured under stringent quality control, from materials to sharpening and final inspection.

Our decades of experience and knowledge enable us to consistently offer quality products that always go above and beyond our customers’ expectations.

Plastic Doctor® Blade

Once purchased you get support and lifetime updates for the theme.

Plastic doctor blades are resistant to organic solvents, oils, grease and acids, as well as weak alkaline solutions. Material options are available among PET, HDPE and POM with different levels of hardness and heat resistance.

Resistant to organic solvents, oils, grease and acids

Available in PET, HDPE and POM with different levels of hardness and heat resistance

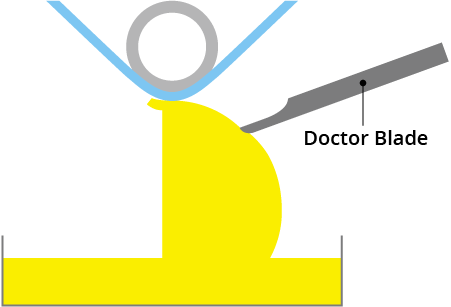

Doctor Blade Basics

The essential part of achieving precise printing

Doctor blades make direct contact with the anilox roller in printing presses to precisely remove excess ink or coating liquid. The material and shape of the blade tip must be selected based on the specific press and application. Choosing the optimal blade ensures consistent and high-quality printing results.

And new ones with every update

who trust Enfold with their site

You got any issues? Get in touch!

of programming effort

We aim for at least a decade!

To change the way your site looks